The Current Facility Management Environment

The facility management business environment is constantly evolving and challenging building owners and facility executives to pause, reflect, and reconsider existing facility maintenance, reliability, and operations methods and practices. The increased business expectations necessitate a change of focus from “Is my facility operational and not experiencing major breakdowns?” to “What is the value that my facility is receiving from facility O&M?”. Simply put, what worked in the past is not good enough anymore.

Proactively, innovative facility leaders are continually trying to understand the value that their facilities will require in the future and their actions to take today to prepare for it. So that when the need arises, they aren’t caught off-guard.

Why should I Evolve?

Today’s business requirements expect facility maintenance, reliability, and operations to pivot towards becoming agile (flexible and responsive) utilizing optimized processes, data-driven approach, and customized best business practices.

The need is to evolve facility maintenance, reliability, and operations techno-commercially to achieve optimal performance and increase the value of facility maintenance. Engaged, trained, and competent resources are essential in delivering the desired reliability, risk mitigation, and cost control.

Traditionally, facility maintenance is usually rigid, task-oriented, and value-oriented. The primary focus is to keep the building operational and generally lacks a structured continuous improvement program and resources to target specific areas for focusing on improvement efforts.

Gaps exist in trying to satisfy today’s business requirements utilizing yesterday’s facility maintenance approaches. These gaps potentially lead to sub-optimal performance, low employee morale, and misalignment with value-driven organizational goals.

What Should I Do About it?

A significant leadership-driven cultural change to challenge the status quo of traditional facility maintenance, reliability, and operations and expecting structured improvements with focused governance is generally the starting point.

The commitment and desire by leadership to establish increased expectations and allocate and prioritize the desired competent resources and efforts are fundamental. Creating a continuous improvement mindset promoting innovation is critical.

Identifying and realizing the current maintenance, reliability, and operations status determines and identifies the wide gaps to the desired end state.

There will be instances where the gaps are small in certain areas, and the goal may be achieved with relative ease or employ a shorter path. In some cases, the holes may be more prominent, and achieving the desired end state may take longer. Depending on where the gaps lie and prioritizing the higher value areas, a roadmap to the desired end state needs to be established.

The roadmap should consist of short-term actions (low-hanging fruit) and a set of long-term activities. The short-term and long-term activities on the roadmap will highlight and communicate the additional value the facility will receive in the short term and proactively lay out the path to prepare and enable long-term value addition.

Every journey requires a clearly defined end-point before the trip begins, along with markers that will indicate progress and along the way. Appropriate metrics and measurements will demonstrate and affirm the value addition to stakeholders.

After establishing the roadmap, the structured continuous improvement program begins. The program requires support and drive from leadership through active governance and to ensure the program’s sustainability. A change management approach to supplement the program implementation may be necessary depending on the resistance to change.

How Can I Do it? What is CPM?

C&W Services Productive Maintenance (CPM) program, based on world-class Total Productive Maintenance (TPM) fundamentals and customized for maintenance service delivery management, is a data-driven, structured continuous improvement framework.

CPM is a Site Team Driven customizable, flexible, and scalable program to ‘Raise the Value.’ The site needs and stakeholder expectations (roadmap) determine the pillars for implementation.

The objectives of CPM are to:

- Establish and enable a structured Continuous Improvement program to improve maintenance, reliability, and operations service delivery

- Establish focused governance to Measure, Track and Communicate Improvement efforts to stakeholders

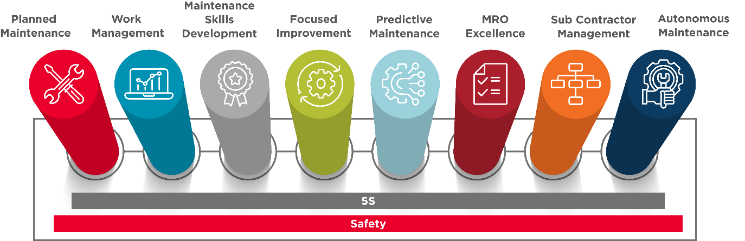

CPM consists of two solid foundational elements (Safety and 5S) and eight pillars, as shown in the graphic below.

CPM consists of standard processes, practices, and focused governance to improve existing facility maintenance, reliability, and operations and mature them to world-class maintenance through continuous improvement and data-driven approaches.

The site team is complemented by one of our Certified Reliability Leaders (CRL), Certified Six Sigma Black Belts, or Maintenance Engineers. The additional expertise will coach and guide the groups through workstreams and activities to help your facility reach the highest levels of performance and efficiency.

What will I achieve? Expected Outcomes:

The quantification of expected outcomes is dependent on the current status of the operation and the desired end state. However, potential achievable benefits are described below,

- Preventive Maintenance Strategy for equipment is based on verified and accurate asset knowledge, rightsizing the maintenance requirements

- Comprehensive maintenance assignments, balanced preventive maintenance calendars, and complete work packages improve work quality and efficiency

- High CMMS utilization enables data-driven decision making for targeted improvements

- Reactive work is minimized through proactive efforts

- Effective work screening and receiving results in improved customer service

- Optimized work management improves employee productivity and efficiency by reducing operational waste

- Work quality assurance through targeted audits and supervision

- Formal reliability practices through proactive defect elimination improve equipment reliability

- Targeted employee training improves employee capability, morale, and engagement

- Sub Contractor work optimization

Implementing the structured CPM framework for continuous improvement, with focused multi-level governance, establishes a sustainable continuous improvement mindset and culture to enable the roadmap and journey to world-class operations.