By Scott R. Burnell

What is deferred maintenance? Deferred maintenance refers to repair activities that are delayed and backlogged due to limited funding or human capital.

Research has shown that delaying maintenance can increase future cost and capital expenditures by as much as 600%. In addition to the high cost of delaying repairs, deferred maintenance contributes to safety hazards, energy inefficiency, and may negatively impact the reputation of your company.

As a contractor, the financial requirement of addressing deferred maintenance is frequently not under our control as this funding is typically out of scope. Despite this, we must understand what the deferred maintenance at a client site is, address as much of it as possible with in-house staff, and finally be able to report it to the client so that it may be included in long-term capital planning. We are hired to improve operational conditions, not kick the can down the road. Having a plan to deal with deferred maintenance and including this in our client communications is crucial to operational and client relationship success.

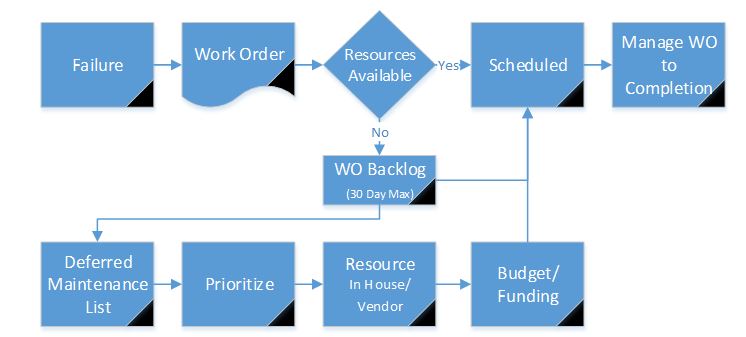

Example workflow:

When deferred maintenance isn’t handled properly it’s usually placed into a maintenance backlog and is sometimes dismissed as unnecessary until capital replacement can be done. This creates a failure cycle that drains available resources. As the repair or replacement is postponed, system failures start increasing at a greater volume and frequency. This increases reactive maintenance and starts to drive up costs that could otherwise have been avoided. Depending on the size of the deferred maintenance list, reactive maintenance will overtake planned maintenance as the cycle continues to grow and resources are diverted to deal with the direct and indirect results of deferring the repair. To avoid this situation, deferred maintenance needs to be identified, recorded and managed.

1. Audit

Conduct an audit. The best approach is to conduct a facility condition assessment so you understand all the deficiencies that fall under the maintenance organizations purview. This should include all the services lines you provide for the associated client.

2. Prioritize

Prioritize deficiencies based on safety, comfort/aesthetics, cost to maintain, and operational efficiency. Understand the scale of maintenance-related issues. Separate the backlog into two categories:

- Immediate Attention: Action needed to return to normal operations or is safety related.

- Delayed Attention: Deficiencies that will become critical if action is not taken within a certain time frame.

To help group activities and drive management decisions, further sub-categorize into the following:

- Trade required, i.e. Electrical, HVAC, General Maintenance, Janitorial, etc.

- Planned resource: in-house or vendor.

- Estimated cost of repair/replacement or upgrade.

- Asset age or percent lifecycle.

- Location of repair.

Having multiple ways to sort the deferred maintenance list will bring clarity to the order of priority in which to tackle what is typically a large and overwhelming list. A good example of this is grouping vendor related work by trade and bidding the work as a package.

3. Manage

Separate deferred maintenance items from the normal day-to-day maintenance items. This can be done by including a hold category of “DEFERRED” in the Computerized Maintenance Management System (CMMS) or by maintaining a separate spreadsheet. The preference is to manage the list separately from the CMMS so that reporting metrics are not negatively impacted. The key is to measure resources on a weekly basis—opening work orders against the deferred maintenance list based on resource availability, track the available hours each week. Developing a trend here will allow the manager to determine if the maintenance team is understaffed and may be able to build a case with the client to hire additional positions instead of outsourcing to a third party at a premium.

4. Report

Review the work order backlog weekly. “Backlog” should be considered work that can be done but is backlogged due to staff issues such as sickness, vacation, staff changes, scheduling, etc. Identify labor availability and drive backlog to a minimum. If the backlog exceeds 30 days, the items should be moved to the deferred maintenance list and managed from there. Once labor availability is achieved, create work orders from the deferred maintenance list according to priority.

Standardize a report that displays current backlog and deferred maintenance items. This should be shared with the entire maintenance staff and client. Regarding backlog, use work order counts as a weekly benchmark. For deferred maintenance use item counts for a benchmark. This is not intended to be detailed but rather show progress week-over-week.

5. Acquire Funding & Resources

Getting additional funding or resources is easier if you can show where your current budget is allocated. A properly categorized deferred maintenance list will show what is needed in terms of funding additional positions, vendor resources, and capital equipment replacement needs. In fact, the deferred maintenance list should be the source of capital funding requests. After you implement a system that helps demonstrate this, you are better equipped to convince client management that increasing short-term profits or budget savings costs more in the long run. Industry-wide benchmarks show that deferred maintenance compounds by 7% per year.

Securing budgetary funding should not be a onetime exercise. Seek creative solutions such as funding at the department level to ease the maintenance budget.

6. Repeat

Although the deferred maintenance list is a live document that will have items added and removed throughout the year, plan an annual site inspection (with the client if they are amenable) to update the list and reset priorities. Schedule this before the capital planning period. A detailed inspection with client interaction helps create a combined vision for the maintenance organization. Stepping out of the day-to-day operations to look at the facility in its entirety can be very enlightening and hopefully not frightening.

For help in developing a plan at your facility feel free to contact me.