By Mario Quispe, HSSE Manager – West Region, C&W Services

When I took over the safety department at a Texas-based financial services company in 2014 where C&W Services provides landscaping, move and changes services, and janitorial and maintenance services, a hearing test existed for only a few employees. Seeing this, we decided to implement an effective hearing conservation program—something that is much more than just a simple test. This program minimizes the risk of employee hearing loss resulting from work-related noise exposure in the workplace. Exposure to high noise levels can cause hearing impairment or even hearing loss, of which there is no cure. Therefore, preventing excessive noise exposure is the best method to avoid hearing damage.

These programs are mandated by OSHA when noise levels are at or above 85 decibels averaged over eight working hours or an eight-hour time-weighted average.

After conducting a site assessment—which is conducted once before the program is implemented and then every year after that—and monitoring noise exposure levels in several work areas, we identified 24 employees that were assigned in six different areas where the noise levels exceeded 85 decibels. Approximately 38 employees were monitored in seven main areas—four areas where trash compactors and shredding machines are located; two with chillers in plant operations; and the entire area outside the property building. So, we implemented the exposure levels with administrative (procedures such as Job Safety Analysis) and personal protective equipment (ear plugs and/or ear muffs) control measures to minimize the noise exposure in these areas.

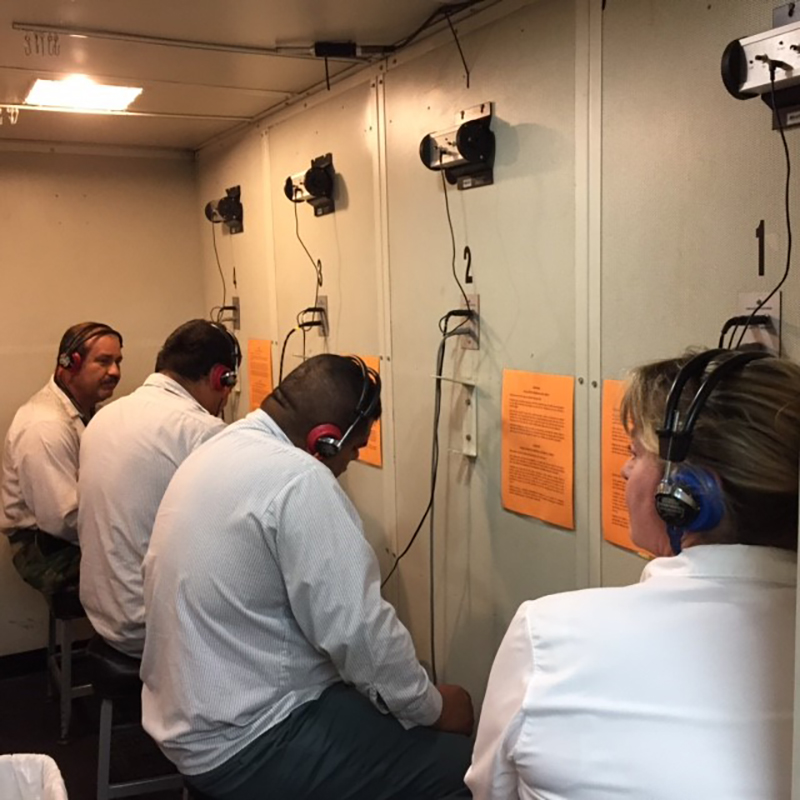

Aside from the site assessment, we also provide free annual hearing audiogram tests. The results give us information that determines whether or not employees are in an acceptable hearing range. They also help us make recommendations for employee job rotation.

After three consecutive years, we noticed success in the program. Three employees showed hearing improvement and the majority showed no significant changes or impairments. Employees were more aware of the exposure of noise levels in the workplace. Also, they became more comfortable using hearing devices at all times. Some employees requested new hearing devices before they wore out because we had taught them the importance of self-inspection. That was a culture change in the mindset of the employees. Providing employees with knowledge and hearing protection devices that are necessary for safeguarding themselves is just one example of how we at C&W Services understand the importance and vitality of ensuring the safety—and contentment—of our employees.